Structural timber flooring: Grown & manufactured locally

Strandfloor and SuperPine by Laminex are structural timber flooring products that are proudly grown and manufactured in New Zealand, pairing a local supply chain with the carbon sequestering properties of wood.

With the push to decarbonise the building industry, building codes globally are being updated to allow for the wider use of mass timber construction. New Zealand architects are well placed to lead in this technology, with direct access to a local supply chain and the ability to speak face-to-face with producers and suppliers.

Laminex structural timber flooring defined

Strandfloor® structural flooring is made from wood strands bonded with a moisture-resistant polymer resin. SuperPine® structural flooring is made from small wood particles bonded with moisture-resistant formaldehyde resin. Both products are subjected to heat and pressure to make 20 mm thick high-density interior flooring panels. Suitable for structural flooring, they can also be used in the Laminex New Zealand Fire and Acoustic Floor System.

With a maximum span of 600 mm between joists, and sheets that lock together with an easy-fit tongue-and-groove system, the panels provide a diaphragm that braces the building. This plays a crucial role in providing stability and structural support. Panels can be overlaid with a range of flooring coverings, including hardwood, carpet, tiles, or vinyl (with a suitable underlay), or be left exposed and finished as a decorative floor surface.

Where to use Laminex structural flooring

Strandfloor, StrandfloorH3.1® and SuperPine by Laminex are specifically made for use as residential and commercial interior flooring platforms within the scope of NZS 3604. They comply with the New Zealand Building Code (NZBC) and NZS 3602:2003 for timber and wood-based products, ensuring structural integrity and performance.

Strandfloor, StrandfloorH3.1 and SuperPine are BRANZ Appraised. Strandfloor and StrandfloorH3.1 are also CodeMark-certified.

Typical applications include:

- Pre-laid or post-laid flooring over traditional, engineered, and steel floor joists in single or double-layer applications.

- Floor diaphragms for wind and earthquake loads.

- Intertenancy floors.

- An overlay for concrete or wooden floors.

- For general staircase construction.

- Carcass panels in cabinetry.

- Industrial shelving and packaging.

- Structural insulated panel (SIP) construction.

Using Laminex structural flooring in wet areas

Strandfloor H3.1® meets NZBC requirements for use in wet areas.

SuperPine can be used in open kitchens and laundries, provided it is protected by a waterproof membrane that complies with AS/NZS 4858 or is covered by a valid BRANZ appraisal. See our Technical Manual for details.

Local manufacturing benefits everyone

For decades, Laminex has supplied products that Kiwis know and trust. These products have been created and developed using New Zealand material by manufacturing plants that understand the NZBC, as well as consumer needs.

Laminex products have been chosen, specified, and installed successfully in thousands of homes and commercial buildings across the country.

And the benefits of a local supply chain extend much further. Proximity to raw resources and to the market means New Zealand-made Laminex wood products have a strong domestic value chain. Sourced from well-managed, sustainable forestry, Laminex products are better for the environment. And local communities also benefit economically.

Panel properties and sizes

Laminex manufactures three types of panel for structural flooring:

- Strandfloor

- Strandfloor H3.1

- SuperPine

All three products are available in two sizes:

- 2400 x 1200 mm

- 3600 x 1200 mm

Panels are 20 mm thick, with tongue-and-groove or square edge* (made to order) finishes. Laminex structural flooring is made using a combination of resins and waxes which are designed to handle eight (Strandfloor and SuperPine) or 12 weeks’ (Strandfloor H3.1) exposure to weathering during construction. These resins and waxes provide the durability of the panel for the specified exposure period.

Strandfloor H3.1 is a treated version of Strandfloor that is specifically designed for use in wet areas.

*minimum order quantities and additional lead times apply

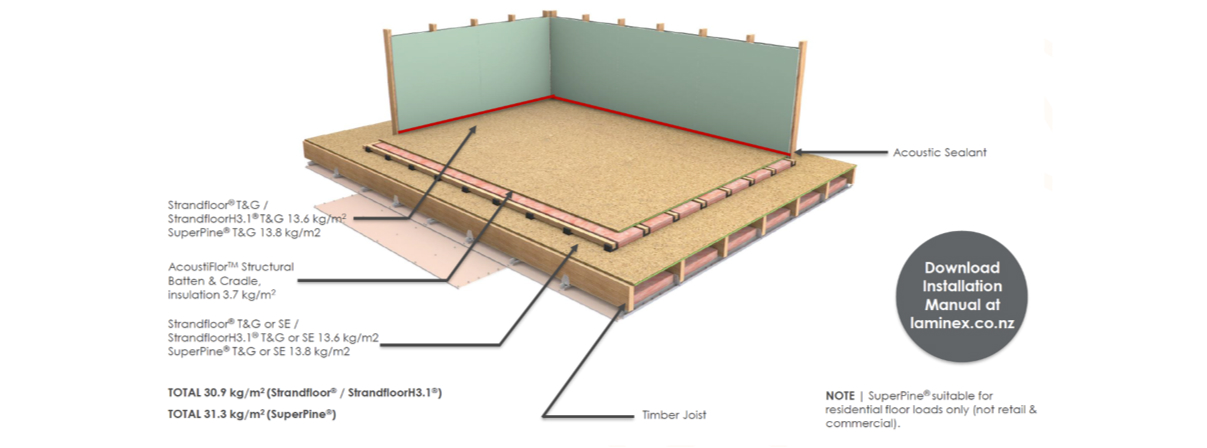

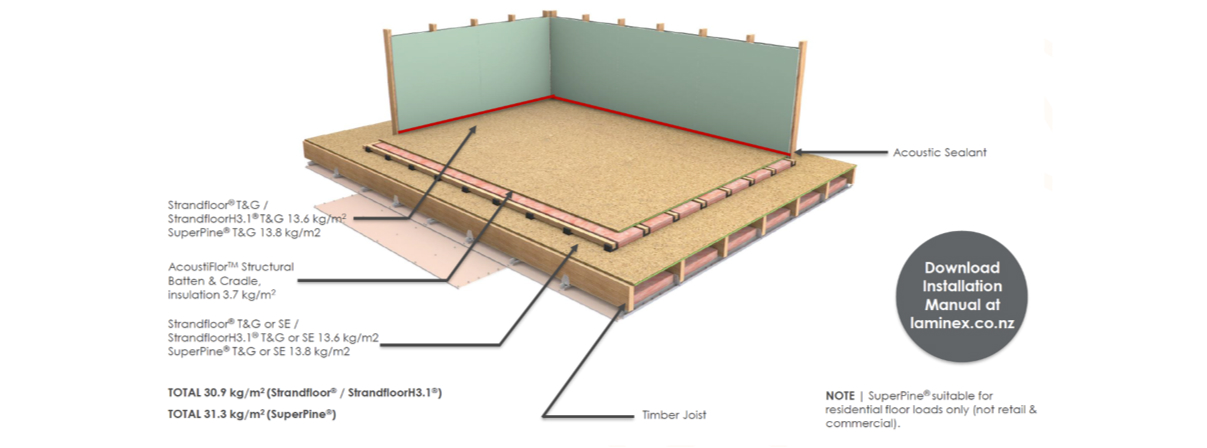

Laminex New Zealand Fire & Acoustic Floor System

The LNZ Fire & Acoustic Floor System, developed by Laminex New Zealand and Batten and Cradle Floor Systems, is a lightweight floor system (above joist weight of approximately 31kg/m2) suitable for use as an intertenancy floor.

This system has been independently tested and verified by BRANZ to achieve fire ratings up to 60/60/60 FRR and STC 65/IIC-56, exceeding the minimum requirements of clause G6 of the NZBC. The acoustic performance of the system has been verified by Marshall Day acoustics and independently tested at the University of Auckland.

The LNZ Fire & Acoustic Floor System is ideal for multi-level residential, health, and aged care buildings, as well as mixed use (office, retail, and residential).

The LNZ Fire & Acoustic Floor System offers excellent acoustic properties, minimising noise transmission and enhancing indoor acoustic comfort. The dense composition of the boards and solid construction effectively dampen sound vibrations, reducing airborne and impact noise within buildings.